Page 116 - Seaward Safety | Supplying Signage Solutions

P. 116

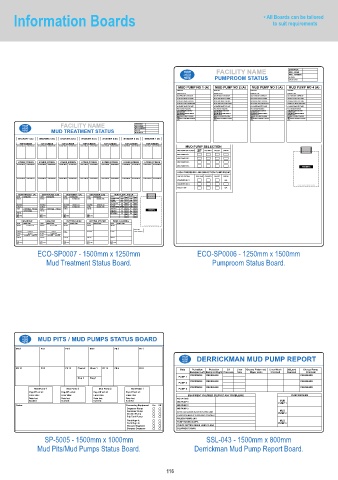

Information Boards * All Boards can be tailored

to suit requirements

YOUR FACILITY NAME OPERATOR

WELL NAME

LOGO WELL NUMBER

HERE PUMPROOM STATUS BLOCK

SPUD DATE

MUD PUMP NO 1 (A) MUD PUMP NO 2 (A) MUD PUMP NO 3 (A) MUD PUMP NO 4 (A)

LINER SIZE LINER SIZE LINER SIZE LINER SIZE

CAPACITY / STK CAPACITY / STK CAPACITY / STK CAPACITY / STK

MAX PRESSURE CYBERBASE MAX PRESSURE CYBERBASE MAX PRESSURE CYBERBASE MAX PRESSURE CYBERBASE

HP RELIEVE VALVE SET POINT HP RELIEVE VALVE SET POINT HP RELIEVE VALVE SET POINT HP RELIEVE VALVE SET POINT

HP RELIEVE VALVE TEST DATE HP RELIEVE VALVE TEST DATE HP RELIEVE VALVE TEST DATE HP RELIEVE VALVE TEST DATE

HP RELIEVE LINE FLUSHED DATE HP RELIEVE LINE FLUSHED DATE HP RELIEVE LINE FLUSHED DATE HP RELIEVE LINE FLUSHED DATE

LP RELIEVE VALVE TEST DATE LP RELIEVE VALVE TEST DATE LP RELIEVE VALVE TEST DATE LP RELIEVE VALVE TEST DATE

PRE-CHARGE PRESSURE PRE-CHARGE PRESSURE PRE-CHARGE PRESSURE PRE-CHARGE PRESSURE

LAST INSPECTION SUCTION LAST INSPECTION SUCTION LAST INSPECTION SUCTION LAST INSPECTION SUCTION

MODULE DATE MODULE DATE MODULE DATE MODULE DATE

LAST INSPECTION DISCHARGE LAST INSPECTION DISCHARGE LAST INSPECTION DISCHARGE LAST INSPECTION DISCHARGE

MODULE DATE MODULE DATE MODULE DATE MODULE DATE

SUCTION STRAINER CLEANED SUCTION STRAINER CLEANED SUCTION STRAINER CLEANED SUCTION STRAINER CLEANED

DATE DATE DATE DATE

DISCHARGE STRAINER CLEANED DISCHARGE STRAINER CLEANED DISCHARGE STRAINER CLEANED DISCHARGE STRAINER CLEANED

DATE DATE DATE DATE

YOUR FACILITY NAME OPERATOR

WELL NAME

LOGO WELL NUMBER

HERE MUD TREATMENT STATUS BLOCK

SPUD DATE

SHAKER 1 (A) SHAKER 2 (B) SHAKER 3 (C) SHAKER 4 (D) SHAKER 5 (E) SHAKER 6 (E) SHAKER 7 (E)

TOP SCREEN TOP SCREEN TOP SCREEN TOP SCREEN TOP SCREEN TOP SCREEN TOP SCREEN

SCREEN MESH: SCREEN MESH: SCREEN MESH: SCREEN MESH: SCREEN MESH: SCREEN MESH: SCREEN MESH: SCREEN MESH: SCREEN MESH: SCREEN MESH: SCREEN MESH: SCREEN MESH: SCREEN MESH: SCREEN MESH:

MUD PUMP SELECTION

MAIN

MUD PUMP SELECTION AUX WELL BOOST SHEAR

WELL

MUD PUMP NO 1

MUD PUMP NO 2

LOWER SCREEN LOWER SCREEN LOWER SCREEN LOWER SCREEN LOWER SCREEN LOWER SCREEN LOWER SCREEN MUD PUMP NO 3

SCREEN MESH: SCREEN MESH: SCREEN MESH: SCREEN MESH: SCREEN MESH: SCREEN MESH: SCREEN MESH: SCREEN MESH: SCREEN MESH: SCREEN MESH: SCREEN MESH: SCREEN MESH: SCREEN MESH: SCREEN MESH:

MUD PUMP NO 4

PERMITS

HIGH PRESSURE LINE SELECTION PUMP ROOM

LINE SELECTION DRILLING STANDBY BOOST SHEAR

SCREEN MESH: SCREEN MESH: SCREEN MESH: SCREEN MESH: SCREEN MESH: SCREEN MESH: SCREEN MESH: SCREEN MESH: SCREEN MESH: SCREEN MESH: SCREEN MESH: SCREEN MESH: SCREEN MESH: SCREEN MESH:

STANDPIPE NO 1 N/A

STANDPIPE NO 2

CLEAR LAMINATE (FRONT COVER)

BOOST LINE N/A

CENTRIFUGE 1 (A) CENTRIFUGE 2 (B) DEGASSER 1 (A) DEGASSER 2 (B) MUD FLOW LINE UP

STATUS ONLINE TIME: STATUS ONLINE TIME: STATUS ONLINE TIME: STATUS ONLINE TIME: SHAKER ONLINE BYPASS

SUCTION SUCTION SUCTION DESANDER TANK SUCTION DESANDER TANK TREATMENT TANKS ONLINE BYPASS

CUTTINGS SKIPS DUMP

GUMBO BOX ONLINE BYPASS

TRIP TANK PUMP 1 (A) 2 (B)

DISCHARGE DISCHARGE DISCHARGE DEGASSER 1 (A) DISCHARGE DEGASSER 1 (A) TRIP TANK 1 (A) 2 (B)

RETURN fl. RETURN fl. RETURN DESANDER TANK RETURN DESANDER TANK POORBOY RETURN TRIPTANK SHAKER

CONVEYOR 1 ON OFF

SOLIDS CONVEYOR DUMP SOLIDS CONVEYOR DUMP PUMP NO. PUMP NO.

CONVEYOR 2 ON OFF PERMITS

RETURN TANK PUMP NO.

CONVEYOR 3 ON OFF

PUMP NO. EM. CONVEYOR ON OFF

LAST LAST LAST LAST

INSPECTION INSPECTION INSPECTION INSPECTION

DATE DATE DATE DATE

DESANDER DESILTER CUTTING DRIER JETTING SYSTEM TANK CLEANING

STATUS ONLINE TIME: STATUS ONLINE TIME: STATUS ONLINE TIME: STATUS ONLINE TIME: STATUS ONLINE TIME:

SUCTION DESANDER TANK SUCTION DESILTER TANK CUTTING SUCTION SUCTION CLEAR LAMINATE (FRONT COVER)

MUD WEIGHT

DISCHARGE DESANDER DISCHARGE DESILTER FLUID DISCHARGE RETURN FUNNEL VISCOSITY

RETURN

RETURN DESILTER RETURN RETURN TANK

SOLIDS SHAKER DUMP SOLIDS SHAKER DUMP

PUMP NO. PUMP NO. REMARKS PUMP NO. PUMP NO.

LAST LAST LAST LAST LAST

INSPECTION INSPECTION INSPECTION INSPECTION INSPECTION

DATE DATE DATE DATE DATE

ECO-SP0007 - 1500mm x 1250mm ECO-SP0006 - 1250mm x 1500mm

Mud Treatment Status Board. Pumproom Status Board.

YOUR

LOGO MUD PITS / MUD PUMPS STATUS BOARD

HERE

Pit 9 Pit 7 Pit 6 Pit 5 Pit 3 Pit 1

YOUR

LOGO DERRICKMAN MUD PUMP REPORT

HERE

Pit 10 Pit 8 Pit 12 Chem 2 Chem 1 Pit 11 Pit 4 Pit 2 Date Pulsation Pulsation Oil Liner Grease Piston rod Liner Wash Oil Level Charge Pump

Dampner Left Dampner Right Pressure Size Wiper seals Checked Checked Checked

PRESSURE PRESSURE PRESSURE

PUMP 1

Slug 2 Slug 1

PRESSURE PRESSURE PRESSURE

PUMP 2

PRESSURE PRESSURE PRESSURE

Mud Pump 4 Mud Pump 3 Mud Pump 2 Mud Pump 1 PUMP 3

Pop-Off set at: Pop-Off set at: Pop-Off set at: Pop-Off set at:

Liner size: Liner size: Liner size: Liner size: EQUIPMENT CHECKED (REPORT ANY PROBLEMS) PUMP REPAIRS

Date last Date last Date last Date last AGITATORS

flushed: flushed: flushed: flushed: MIX PUMP 1 MUD

PUMP 1

Notes: Processing Equipment On Off MIX PUMP 2

Degasser Pump MIX PUMP 3

Desander Pump REPORT ANY LEAKING VALVES OR PLUGGED LINES MUD

Desilter Pump PUMP 2

Trip Tank Pump SPARE PISTON MADE UP TO ROD READY TO INSTALL?

WILDEN PUMPS OK?

Centrifuge A PUMP ROOMS SUMPS MUD

Centrifuge B PUMP 3

Vacuum Degasser CHECK SUCTION DRAIN LINES CLEAR

Burgess Degasser EQUIPMENT DOWN

SP-5005 - 1500mm x 1000mm SSL-043 - 1500mm x 800mm

Mud Pits/Mud Pumps Status Board. Derrickman Mud Pump Report Board.

116